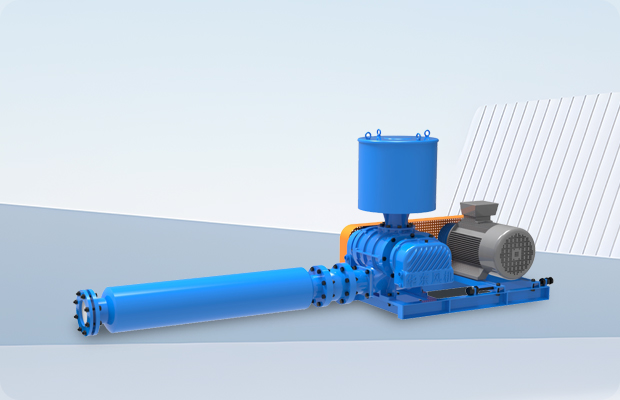

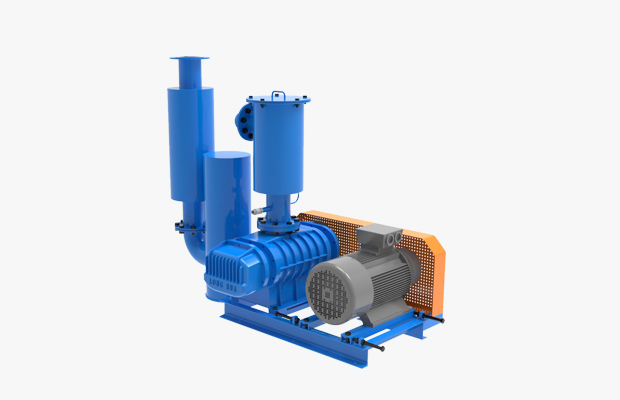

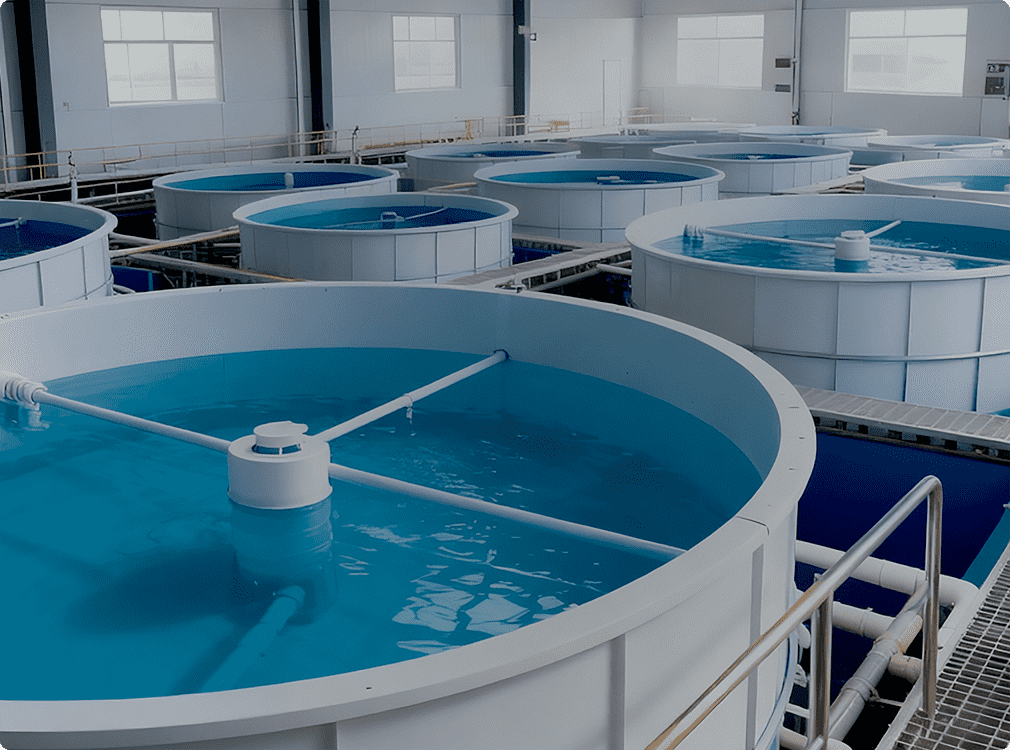

磁悬浮高速离心鼓风机采用了高速永磁同步电机的直驱结构,将离心叶轮和电机驱动一体化集成设计,它通过内置的位移传感器实时检测转子轴的振动及空间间隙,将得到的信号送入磁悬浮轴承控制器进行调理、解析、运算,产生控制电流,再将该电流输入磁轴承绕转线圈,产生电磁力,从而实现转子轴的悬浮。

永磁同步电机的主要功能是驱动转子轴的旋转,它通过变频器产生频率可控的电流,将此电流输入电机定子产生的旋转磁场,带动转子轴高速旋转。

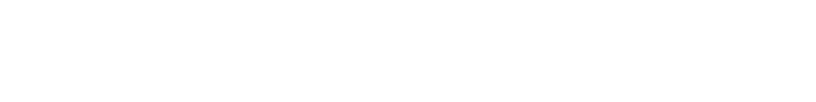

风机的主要功能是实现鼓风,随转子轴一同做高速旋转的叶轮带动空气,对空气做功,空气从蜗壳的进气口集流器进入,空气在蜗壳的导向与增压作用下成为具有一定流速与压力的气体,最后从蜗壳的出气口鼓出实现一定压力和流量气体的输送。

Magnetive levitation centrifugal blower uses the direct driving structure of high rotary speed permanent magnet motor, de-signed together with centrifugal impeller and motor driving. It monitors the vibration of shaft and space gap by the motion dtector inside. Then it would transfer the signal to the magnetive levitation bearing controller to adjust, parsing, calculation, and producing controlling current, to transport the current into the magnetive bearing winding coil, and producing electromagneticforce, then realize the levitation of shaft.

The main function of permanent magnet synchronous motor is to driving the rotary of shaft. It produce the frequency con-trollable current,and transport the current into the rotary magnetic field of motor stator,to drive the shaft rotaryin a higher speed.

The blower's main function is to boosting air.The impeller, which whirling together with shaft,works on air.Air enters fromthe inlet collector of the volute, and the air becomes a gas with a certain flow rate and pressure under the guidance and pressur-ization of the volute, and finally blows out from the air outlet of the volute,to realize a gas delivery process with certain pressureand flow rate.